- 2024 HONOREE

- Jewel Box

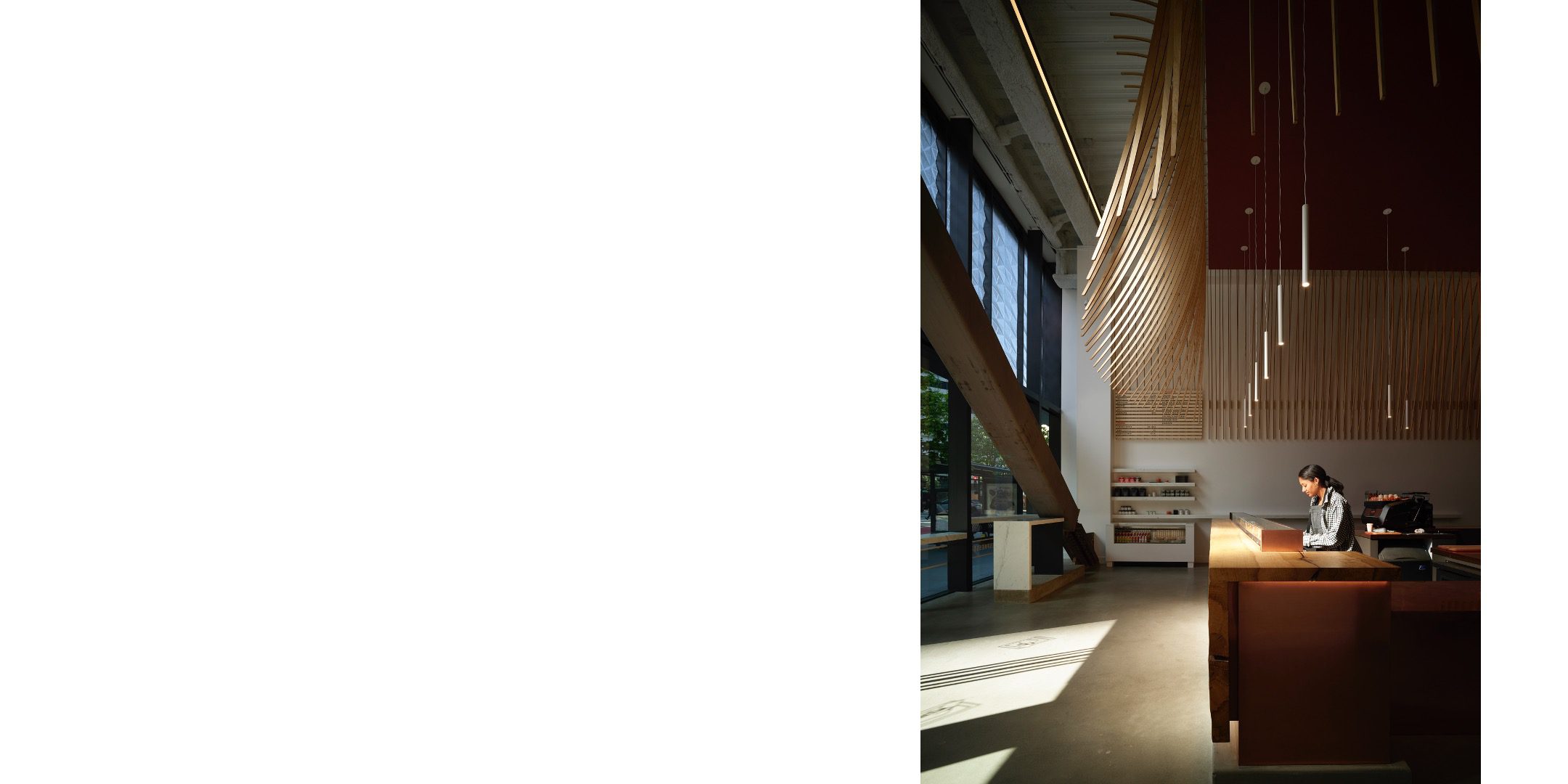

The Caffé by Mr. Espresso

jones | haydu

Design Team

jones | haydu

Hulett Jones

Design Principal in Charge

Paul Haydu

Principal

Grace Leung

Project Architect

Aaron Goldman

Studio Director

Oliver Vogler

Project Architect

Kate Sistek

Project Manager

Eric Dell’Orco

Designer

About the Project

The Italians have a word for the ritual of stepping into a caffe and enjoying espresso at the bar. They call it a “pausa” or a pause — a moment in one’s day that allows for reflection and community. The goal was to design a space that is in harmony with this notion and to treat the most basic daily ritual and experience as meaningful, as a form of art.

The design was informed heavily by Italian cuisine, which is masterful at creating great complexity with minimal ingredients. We chose to keep the number of materials used in the cafe to a minimum and to celebrate their innate richness. The primary bar, where people commune, is crafted from slabs of a single white oak tree that fell in Sonoma County in 2008. Great care was taken to leave the slabs intact as much as possible, cleaned up just enough for food safety. Copper is hand polished and sealed. Along the perimeter of the caffe is a resting ledge which is made from Calacatta marble, a nod to one of Italy’s most ubiquitous yet luscious materials.

Our initial designs for the overhead portion were more architectural in nature, required substantially more structure and material (and thus cost) than was feasible. Though we felt the design of the bar was substantive and could hold its own, we truly wanted there to be art in the space, and we were confident that it needed to be sculptural in nature. As such, we made a pledge to design and construct something —on our own— that would be relatively cost effective.

There are 272 slats formed from a total of 528 pieces, all made of birch plywood, CNC’d, designed and laid out to minimize waste. Each slat is roughly 12’ in length, 2” wide tapering to ¾”, and weighing roughly two pounds. Prototypes were made and tested at the architect’s office. Final slats were assembled, glued, and stained by the architects at the client’s warehouse. Many different staining processes were tested. The final stain was achieved with Ethiopian Shantawene coffee, brewed quite strong, and wet applied. Once dry, the slats were hand rubbed with beeswax.

The piece was installed by the architect over a five-day period. Installation was performed back to front, as once in place, the curvature made raising a scissor lift for access very difficult. Many precautions were taken to maintain alignments, most worked out in the prototype phase, including jigs and pre-drilling. Even so, due to fluctuations in the mounting surface, how the screws bit into the substrate, and in the slats themselves (some bending out of alignment), alterations were made during installation, including addition of shims. Final alignments were made using fishing line.

Client Statement

At the time our father planted roots in the Bay Area, in the U.S., very little was known about espresso. It wouldn’t be inaccurate to say few Americans had ever drank an espresso. Even fewer knew the intricacies of how to make one. But as Italian culture began to permeate the Bay Area from epicenters such as San Francisco’s North Beach, our father identified the necessity to bridge the gap between our family’s past and what is now our family’s future: to popularize excellent espresso as imperative to a good meal. Mr. Espresso became the roaster of choice for some of the Bay Area’s finest cafes and restaurants. Chefs such as Alice Waters, Bradley Ogden and Paul Bertolli and restaurants like Square One and The Baywolf began to take notice. The coffee grew and expanded not only because of its taste, but also because of its story. At the same time, the story of Mr. Espresso is a reminder of just what it means to be an American. This story is a living example of how our diverse cultural landscape was nourished by the efforts of those eager to share their heritage with the rest of the world.